A quality product is one that meets the requirements placed on it. Therefore, we focus on the wishes of our customers and according to them we manage all processes so that we achieve this quality.

TURNING WORK

turning work on classic lathes to an average 1500 mm, L= 2000 mm, accuracy 0,2 mm, L = 100 mm, accuracy 0,05 mm

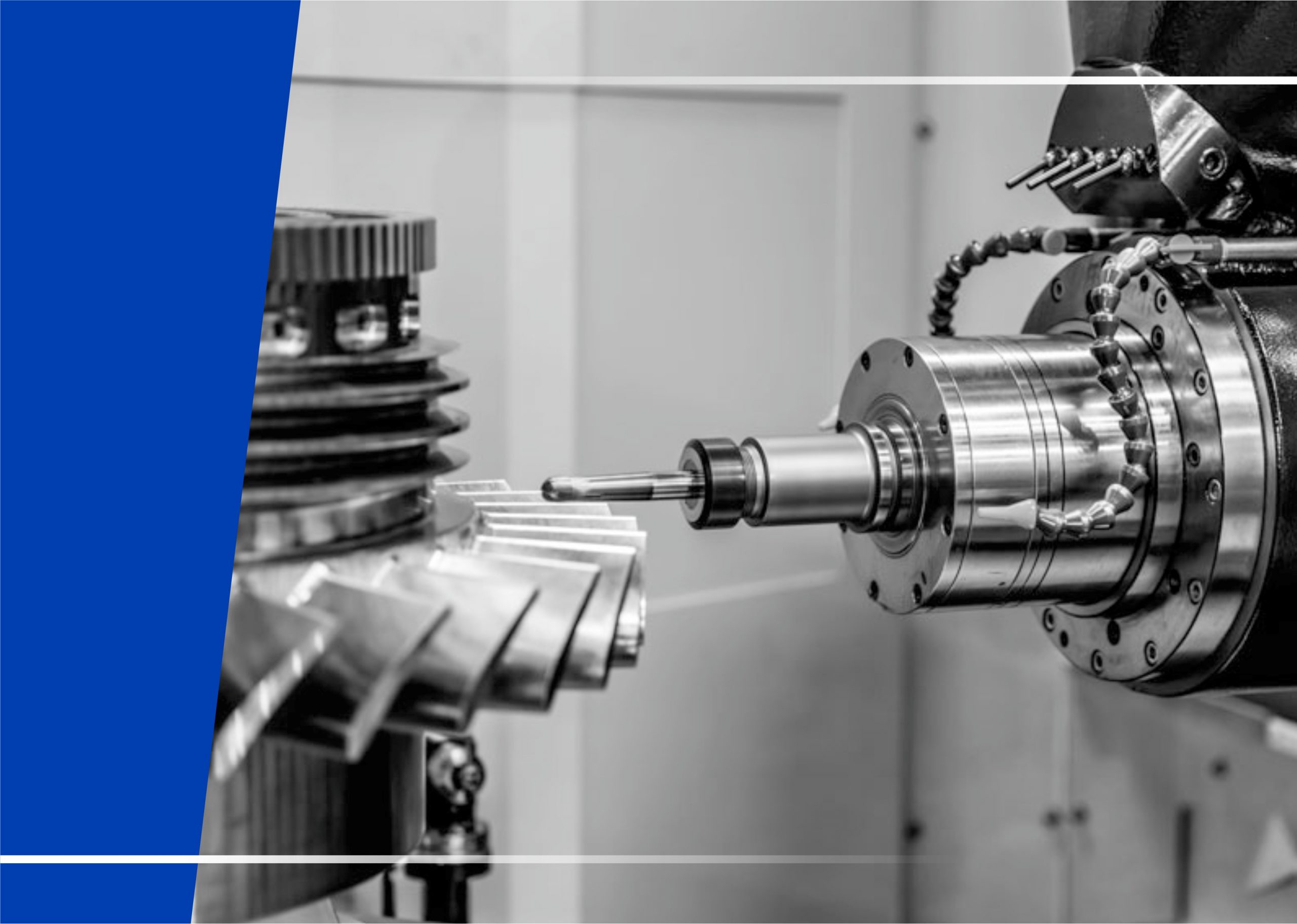

CNC TURNING

CNC turning to diameter 1200 mm, L= 800 mm, accuracy 0,03 mm milling

MILLING AND BORING

milling and boring on classic horizontal milling machines to 1000 x 600 x 1500 mm, accuracy 0,03 mm

milling of planar surfaces to 1000 x 3000 x 600 mm, accuracy 0,2 mm, do 1000 x 1000 x 600 mm, accuracy 0,03 mm

drilling holes on jig boring machines into 1500 x 1000 x 450 mm, accuracy 0,02 mm

CNC MILLING AND BORING

CNC milling and drilling into 3500 x 2000 x 1200 mm, accuracy 0,05 mm, do 1600 x 1000 x 600 mm, accuracy 0,03 mm

GRINDING OF MATERIALS

grinding of planar surfaces to 800 x 2000 mm, accuracy 0,05 mm, do 400 x 2000 mm, accuracy 0,02 mm , do 300 x 800 mm, accuracy 0,01 mm

grinding of shaft components to diameter 300 mm, L= 1500 mm, accuracy 0,01 mm

grinding holes to diameter 300 mm L = 300, accuracy 0,01 mm

MATERIAL DIVISION

division of rod material into diameter 460 mm

NC separation of material with acetylene to 2 000 x 3500 mm, ± 0,4 mm do hrúbky 100 mm

HEAT TREATMENT / CEMENTATION / BLACK

heat treatment of parts ( hardening to dimensions 1000 x 2000 x 800 mm, T max. = 10000C

cementation to average 600 x 750 mm, tempering and annealing)

blackening of steel parts to 300 x 300 x 600 mm

WELDING AND ASSEMBLY

welding in a protective atmosphere